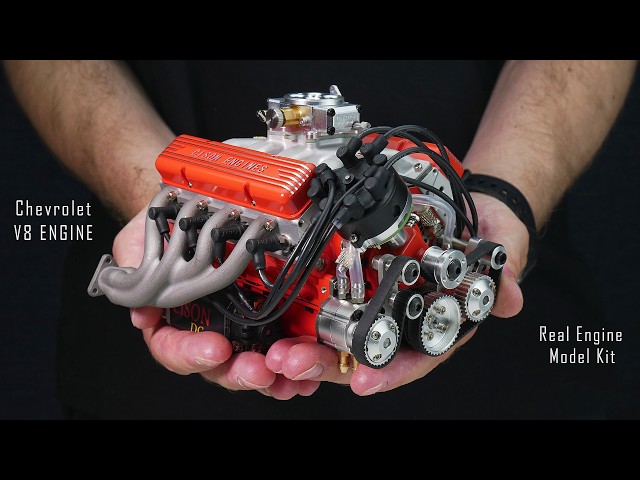

How to Make a Mini Car From a V8 Engine

Building a mini car from a V8 engine is a challenging but rewarding project. It requires careful planning, fabrication skills, and a deep understanding of automotive mechanics. However, the end result can be a truly unique and impressive vehicle.

There are many different ways to approach this project, but some of the most common steps include:

- Choosing a donor car. The first step is to choose a donor car that will provide the V8 engine and other necessary components. Some popular choices include the Chevrolet Camaro, Ford Mustang, and Pontiac Firebird.

- Removing the engine and drivetrain. Once you have chosen a donor car, you will need to remove the engine and drivetrain. This is a complex process that requires special tools and knowledge.

- Building the frame. The next step is to build the frame for your mini car. This can be done using a variety of materials, but steel is a popular choice due to its strength and durability.

- Mounting the engine and drivetrain. Once the frame is complete, you can mount the engine and drivetrain. This process requires careful alignment and precision.

- Fabricating the body. The final step is to fabricate the body of your mini car. This can be done using a variety of materials, but fiberglass is a popular choice due to its lightweight and affordability.

Once you have completed these steps, you will have a fully functional mini car that is powered by a V8 engine. This is a truly unique and impressive vehicle that is sure to turn heads wherever you go.

Here are some of the benefits of building a mini car from a V8 engine:

- You can create a truly unique vehicle. There is no other car on the road that will be exactly like yours.

- You can learn a lot about automotive mechanics. This project will give you a deep understanding of how cars work.

- You can save money. Building a mini car from a V8 engine can be much cheaper than buying a new car.

- You can have a lot of fun. This project is a great way to challenge yourself and learn new skills.

If you are interested in building a mini car from a V8 engine, there are many resources available to help you get started. There are books, websites, and forums that can provide you with information and advice. You can also find kits that can help you with the build process.

With careful planning and execution, you can build a mini car from a V8 engine that is both unique and impressive. This is a project that is sure to bring you years of enjoyment.

Key Aspects of Building a Mini Car From a V8 Engine

Building a mini car from a V8 engine is a complex and challenging project, but it can also be very rewarding. There are many different aspects to consider when undertaking such a project, including the following seven key aspects:

- Engine selection: The choice of engine will have a major impact on the performance and character of your mini car.

- Frame design: The frame is the foundation of your mini car, and it must be strong enough to support the engine and drivetrain.

- Body fabrication: The body of your mini car can be made from a variety of materials, but fiberglass is a popular choice due to its lightweight and affordability.

- Suspension and steering: The suspension and steering systems are responsible for handling and stability.

- Brakes: The brakes are essential for safety, and they must be properly sized and installed.

- Electrical system: The electrical system powers the lights, ignition, and other accessories.

- Safety features: Safety features such as seat belts and roll bars are important for protecting the driver and passengers in the event of an accident.

These are just a few of the key aspects to consider when building a mini car from a V8 engine. By carefully considering each of these aspects, you can build a mini car that is both safe and fun to drive.

Engine selection

The engine is the heart of any car, and this is especially true for mini cars. The type of engine you choose will have a major impact on the performance, character, and overall driving experience of your mini car.

There are many different factors to consider when choosing an engine for your mini car, including:

- Power: The power of the engine will determine how fast and powerful your mini car is.

- Torque: The torque of the engine will determine how much pulling power your mini car has.

- Fuel efficiency: The fuel efficiency of the engine will determine how far your mini car can travel on a gallon of gas.

- Reliability: The reliability of the engine will determine how often your mini car needs to be repaired.

- Cost: The cost of the engine will vary depending on the type of engine and its performance.

Once you have considered all of these factors, you can start to narrow down your choices. If you are looking for a mini car that is fast and powerful, you will need to choose an engine with a high horsepower and torque rating. If you are looking for a mini car that is fuel efficient, you will need to choose an engine with a high fuel economy rating. If you are looking for a mini car that is reliable and affordable, you will need to choose an engine that has a good reputation for reliability and is priced within your budget.

Here are some examples of popular V8 engines that are used in mini cars:

- Chevrolet Small Block V8: This is a popular choice for mini cars because it is relatively small and lightweight, yet it produces a lot of power.

- Ford Windsor V8: This is another popular choice for mini cars because it is also relatively small and lightweight, and it is known for its reliability.

- GM LS V8: This is a newer engine that is becoming increasingly popular for mini cars because it is very powerful and efficient.

Ultimately, the best engine for your mini car will depend on your individual needs and preferences. By carefully considering all of the factors involved, you can choose an engine that will help you achieve your desired performance, character, and driving experience.

Frame design

The frame is the foundation of your mini car, and it must be strong enough to support the engine and drivetrain. This is especially important for mini cars, as they are typically lightweight and have a high power-to-weight ratio. A well-designed frame will help to ensure that your mini car is safe and handles well.

- Strength: The frame must be strong enough to withstand the forces generated by the engine and drivetrain. This is especially important for mini cars, as they are typically lightweight and have a high power-to-weight ratio.

- Rigidity: The frame must be rigid enough to prevent the body from flexing and twisting. This is important for handling and safety.

- Weight: The frame should be as light as possible without sacrificing strength or rigidity. This will help to improve the performance and fuel economy of your mini car.

- Cost: The cost of the frame will vary depending on the materials and design. It is important to find a balance between cost and performance.

There are many different materials that can be used to build a frame for a mini car. Some of the most common materials include steel, aluminum, and fiberglass. Each material has its own advantages and disadvantages, so it is important to choose the right material for your needs.

Once you have chosen a material, you will need to design the frame. The design of the frame will depend on the size and weight of your mini car, as well as the type of engine and drivetrain you are using. It is important to consult with a qualified engineer to ensure that the frame is designed properly.

The frame is a critical component of any mini car. By carefully designing and building the frame, you can ensure that your mini car is safe, handles well, and performs to your expectations.

Body fabrication

The body of your mini car is an important part of the overall design, and it can have a significant impact on the performance, handling, and overall driving experience. When choosing a material for your mini car body, there are many factors to consider, including weight, strength, durability, and cost.

- Weight: The weight of the body will affect the performance and handling of your mini car. A heavier body will slow down your car and make it more difficult to handle. Fiberglass is a lightweight material, which makes it a good choice for mini cars.

- Strength: The strength of the body will determine how well it can withstand impacts and damage. Fiberglass is a strong material, but it is not as strong as steel or aluminum. However, it is still strong enough to provide adequate protection for the driver and passengers.

- Durability: The durability of the body will determine how long it will last. Fiberglass is a durable material, but it can be damaged by UV rays and other environmental factors. It is important to protect the body of your mini car from the elements to ensure that it lasts for many years.

- Cost: The cost of the body will vary depending on the material and design. Fiberglass is a relatively affordable material, which makes it a good choice for budget-minded builders.

Fiberglass is a popular choice for mini car bodies because it is lightweight, strong, durable, and affordable. However, it is important to note that fiberglass is not as strong as steel or aluminum, and it can be damaged by UV rays and other environmental factors. It is important to protect the body of your mini car from the elements to ensure that it lasts for many years.

Suspension and steering

In the context of building a mini car from a V8 engine, the suspension and steering systems play a crucial role in ensuring the vehicle’s handling and stability. These systems work together to control the movement of the wheels and tires, allowing the driver to safely navigate the vehicle and maintain control under various driving conditions.

- Suspension: The suspension system absorbs shocks and vibrations caused by uneven road surfaces, providing a smooth and comfortable ride. It also helps keep the tires in contact with the ground, which is essential for maintaining traction and control.

- Steering: The steering system allows the driver to control the direction of the vehicle by turning the steering wheel. It consists of a series of components, including the steering wheel, steering column, and tie rods, which work together to translate the driver’s input into the desired wheel movement.

When building a mini car from a V8 engine, careful consideration must be given to the design and implementation of the suspension and steering systems. The weight distribution and power output of the V8 engine can significantly impact the handling characteristics of the vehicle. Therefore, it is essential to select appropriate suspension components and steering geometry to ensure optimal stability and control.

By understanding the connection between suspension and steering systems and their role in handling and stability, builders can make informed decisions during the design and construction process of their mini cars. This knowledge helps ensure that the finished vehicle is not only powerful but also safe and enjoyable to drive.

Brakes

In the context of building a mini car from a V8 engine, the brakes play a crucial role in ensuring the safety and control of the vehicle. The power and performance of a V8 engine demand a braking system that is capable of effectively slowing down and stopping the car under various driving conditions.

- Stopping Power: The brakes must provide sufficient stopping power to bring the mini car to a complete stop from high speeds. This requires brake components that are properly sized and designed to handle the weight and momentum of the vehicle.

- Heat Dissipation: The brakes generate a significant amount of heat during operation, especially during repeated or heavy braking. The brake system must be designed to dissipate this heat effectively to prevent brake fade and ensure consistent performance.

- Brake Balance: The brakes must be properly balanced to ensure that all four wheels contribute equally to the braking effort. This prevents the vehicle from pulling to one side during braking and maintains stability.

- Installation and Maintenance: Proper installation and regular maintenance of the brake system are crucial for optimal performance and safety. This includes ensuring that the brake pads are replaced when worn, the brake fluid is flushed periodically, and the brake lines are inspected for any damage.

By understanding the importance of brakes and the factors that affect their performance, builders can make informed decisions when selecting and installing the brake system for their mini car. This knowledge helps ensure that the finished vehicle meets the highest standards of safety and provides the driver with confidence and control behind the wheel.

Electrical system

In the context of building a mini car from a V8 engine, the electrical system plays a crucial role in providing power to essential components and accessories. Understanding the connection between the electrical system and the overall functionality of the mini car is essential for successful completion of the project.

The electrical system is responsible for powering various components, including:

- Lights: The electrical system provides power to the headlights, taillights, brake lights, and turn signals, ensuring visibility and safety during operation.

- Ignition: The electrical system supplies power to the ignition system, which is responsible for starting the V8 engine.

- Accessories: The electrical system powers various accessories, such as the radio, wipers, and power windows, enhancing the comfort and convenience of the mini car.

When building a mini car from a V8 engine, careful consideration must be given to the design and implementation of the electrical system. The power requirements of the V8 engine and the various accessories need to be accurately assessed to ensure that the electrical system is capable of meeting these demands.

Proper wiring, circuit protection, and grounding are essential aspects of the electrical system. The electrical components must be securely connected and protected from short circuits and overloads to ensure reliable operation and prevent potential hazards.

By understanding the connection between the electrical system and the overall functionality of the mini car, builders can make informed decisions during the design and construction process. This knowledge helps ensure that the finished vehicle is not only powerful and efficient but also safe and enjoyable to drive.

Safety features

In the context of building a mini car from a V8 engine, incorporating appropriate safety features is crucial to ensure the well-being of the occupants and mitigate the risks associated with operating a high-performance vehicle.

- Seat Belts: Seat belts are a fundamental safety feature that restrain the driver and passengers in the event of a collision, preventing them from being ejected from the vehicle. They significantly reduce the risk of severe injuries or fatalities.

- Roll Bars: Roll bars are structural reinforcements installed within the passenger compartment to protect occupants in the event of a rollover accident. They provide additional support to the roof and pillars, preventing the vehicle from collapsing and crushing the occupants.

- Impact-Absorbing Materials: Impact-absorbing materials, such as foam and padding, can be strategically placed within the interior of the mini car to absorb and dissipate energy during a collision. This helps reduce the impact forces on the occupants, minimizing the risk of injuries.

- Fire Suppression System: A fire suppression system can be installed to quickly extinguish any potential fires that may occur due to an accident or engine malfunction. This system can help prevent the spread of flames and protect the occupants from smoke inhalation.

By incorporating these safety features into the design and construction of a mini car with a V8 engine, builders can enhance the overall safety of the vehicle and provide peace of mind to the driver and passengers. Prioritizing safety measures is essential to ensure that the mini car is not only powerful and exciting to drive but also a responsible and protective vehicle.

Building a mini car from a V8 engine is an ambitious project that combines engineering skills and automotive enthusiasm. It involves modifying and assembling various components to create a unique and compact vehicle powered by a potent V8 engine.

This undertaking offers several advantages. Firstly, it allows for the creation of a one-of-a-kind vehicle that stands out from mass-produced cars. Secondly, the combination of a lightweight mini car body with a powerful V8 engine results in an exhilarating driving experience characterized by impressive acceleration and handling.

To embark on this project, a deep understanding of automotive mechanics and fabrication techniques is essential. The process typically involves sourcing a donor car for the V8 engine and drivetrain, designing and building a custom frame, fabricating the body panels, and integrating all components into a functional vehicle. Safety features such as seat belts, roll bars, and proper braking systems must also be incorporated to ensure the safety of the driver and passengers.

FAQs

Building a mini car from a V8 engine is an exciting project, but it also raises several common questions and concerns. Here are answers to some of the most frequently asked questions to help you navigate this endeavor.

Question 1: What are the key considerations when choosing a V8 engine for a mini car?

Answer: When selecting a V8 engine, factors to consider include its power, torque, fuel efficiency, reliability, and cost. Choose an engine that aligns with your desired performance and budget.

Question 2: What materials are commonly used to build the frame of a mini car?

Answer: Steel, aluminum, and fiberglass are popular choices for mini car frames. Steel offers strength, aluminum provides lightness, and fiberglass combines affordability and durability.

Question 3: How can I ensure the safety of my mini car?

Answer: Incorporate safety features such as seat belts, roll bars, impact-absorbing materials, and a fire suppression system. Adhere to proper engineering practices and obtain professional inspections to guarantee the structural integrity and reliability of your vehicle.

Question 4: What is the best way to fabricate the body panels of a mini car?

Answer: Fiberglass is a widely used material for mini car bodies due to its lightweight, affordability, and ease of shaping. Employ proper techniques, such as vacuum infusion or hand layup, to create strong and aesthetically pleasing body panels.

Question 5: How do I integrate the engine, drivetrain, and suspension into the mini car?

Answer: Careful planning and precise execution are crucial. Design and fabricate custom mounts and brackets to securely install the engine and drivetrain. Integrate the suspension system to provide optimal handling and stability.

Question 6: What are the legal implications of building and operating a mini car?

Answer: Familiarize yourself with local regulations regarding vehicle construction and registration. Obtain necessary permits and inspections to ensure your mini car meets safety and emission standards.

Summary: Building a mini car from a V8 engine requires careful planning, engineering expertise, and attention to safety. By addressing common questions and concerns, this FAQ provides valuable guidance to help you navigate this challenging yet rewarding project.

Transition to the next article section: To delve deeper into the intricacies of mini car construction, explore the following sections:

Conclusion

The creation of a mini car powered by a V8 engine is a testament to human ingenuity and the pursuit of automotive excellence. This challenging endeavor demands a deep understanding of mechanics, fabrication, and safety principles. By carefully considering the aspects outlined in this article, you can embark on this journey with confidence and build a mini car that embodies your vision.

Remember, meticulous planning, precision execution, and unwavering attention to detail are the cornerstones of success in this undertaking. Embrace the learning opportunities along the way, and never compromise on safety. Whether you intend to turn heads on the streets or conquer the race track, your mini car will serve as a symbol of your dedication and passion for automotive engineering.

Youtube Video: